-

Deixe um recado : info@aabindustrygroup.com

-

Telefone : +86 13951823978

Deixe um recado : info@aabindustrygroup.com

Telefone : +86 13951823978

Aditivos de revestimento são um componente importante das formulações de revestimentos. Embora sua dosagem seja geralmente pequena (0,1% a 5%), eles têm um impacto significativo na estabilidade de armazenamento, no desempenho da aplicação, no efeito de formação de filme e nas propriedades finais do filme dos revestimentos. Princípio de seleção de aditivos para revestimentos: alta eficiência, impacto negativo mínimo, alta relação custo-benefício e conformidade com os requisitos ambientais. A seguir, apresentamos o método de seleção e as principais considerações para aditivos de revestimento.

1. Principais categorias e funções dos aditivos de revestimento

Classificação | Função | Exemplo |

Dispersante | Melhora a dispersibilidade do pigmento, previne sedimentação e floculação | Poliacrilato ae Ésteres de Fosfato |

Agente umectante | Reduz a tensão superficial e melhora a molhabilidade do substrato | Silício orgânico ae Alquinediol |

Antiespumante | Restringe a produção de espuma e reduz defeitos de revestimento | Óleos Minerais; Silício orgânico |

Agente de nivelamento | Melhora o nivelamento do revestimento e reduz marcas de casca de laranja e pincel | Éster acrílico ae Organossilício |

Espessante | Ajuste a viscosidade do revestimento para evitar flacidez e sedimentação | Éter de celulose, poliuretano, bentonita |

Agente anti-sedimentação | Evita a sedimentação de pigmentos e melhora a estabilidade do armazenamento | Sílica em fase gasosa, cera de poliamida |

Acelerador de cura | Acelere a cura do revestimento e melhore a eficiência da reação | Estanho orgânico, amina |

Acelerador de cura | Previne a degradação UV e melhora a resistência às intempéries | UV Absorventes, Hals |

Fungicida | Inibe o crescimento de mofo e prolonga a vida útil do revestimento | Isotiazolinonas, Benzimidazóis |

Promotor de Adesão | Melhorar a adesão entre o revestimento e o substrato | Agente de acoplamento de silano, éster de fosfato epóxi |

2. Fatores-chave na seleção de aditivos

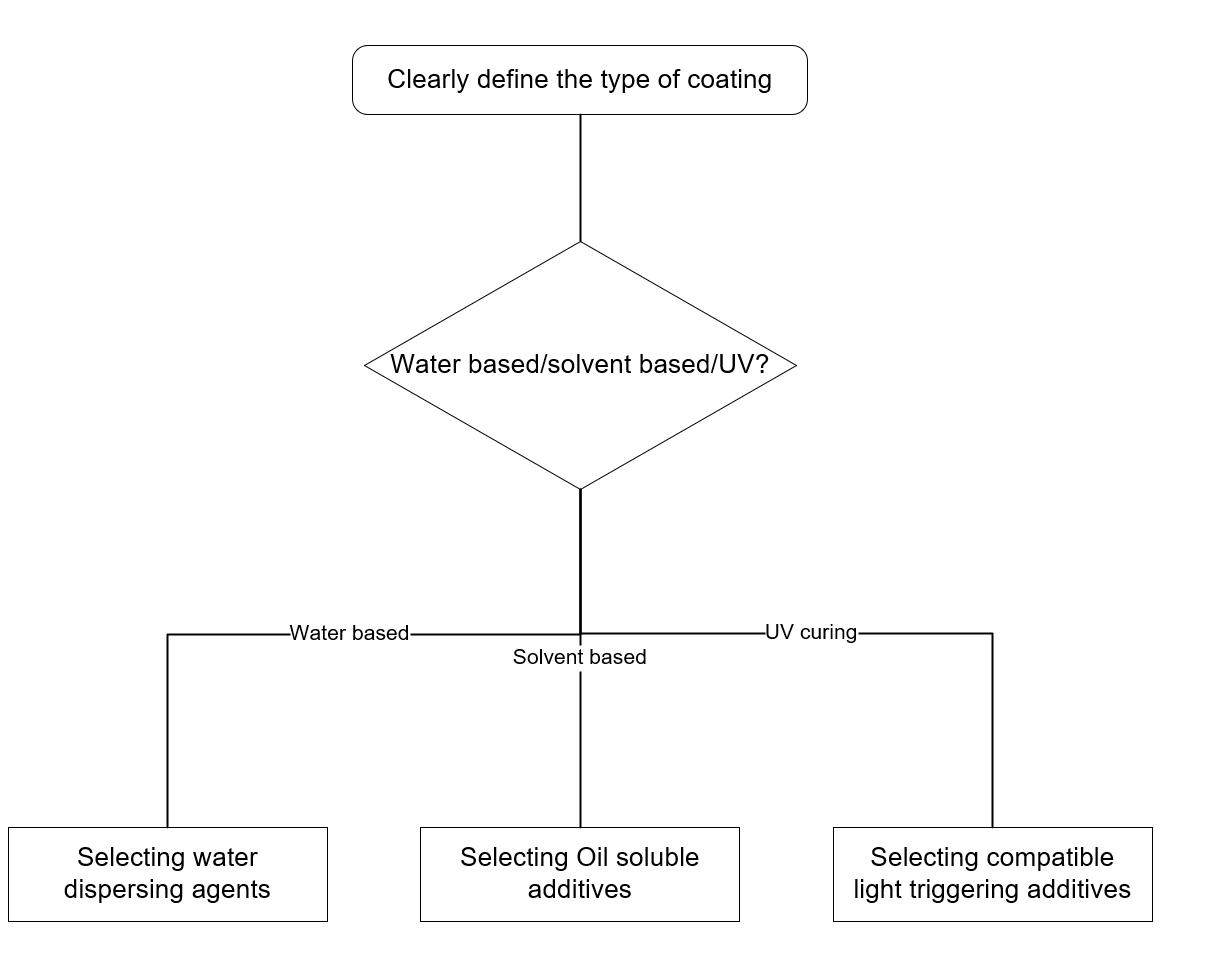

(1) Sistema de revestimento (à base de água/à base de solvente/cura UV)

l Revestimentos à base de água: devem ser selecionados aditivos solúveis em água ou dispersíveis em água (como dispersante BYK-190, agente umectante Tego Wet 270).

l Revestimentos à base de solvente: devem ser selecionados aditivos solúveis em óleo (como o agente de nivelamento BYK-161, o antiespumante BYK-011).

l Revestimentos de cura UV: devem ser selecionados aditivos compatíveis com fotoiniciadores (como o agente de nivelamento Tego Rad 2100).

(2) Tipo de revestimento (primer/acabamento/verniz/tinta colorida)

l Primer: Foco em promotores de adesão e inibidores de ferrugem (como fosfato de zinco).

l Acabamento: As principais considerações incluem agentes de nivelamento, agentes de fosqueamento (como pó de sílica para fosqueamento) e aditivos resistentes às intempéries.

l Tinta colorida: dispersante de tinta à base de água, agente antissedimentação.

(3) Método de construção (revestimento por pulverização/revestimento por pincel/revestimento por rolo)

l Revestimento por pulverização: são necessários aditivos de baixa formação de espuma e agentes niveladores.

l Revestimento com pincel/rolo: são necessários agentes anti-flacidez e anti-respingos.

3. Requisitos ambientais e de desempenho

Demanda | Aditivos Recomendados |

Resistência às intempéries | Absorvente UV+Hals |

Alto brilho | Agente nivelador + antiespumante |

Fosco/Fosco | Pó Matte + Agente Antissedimentante |

Anti-Bactérias

| Inibidor de mofo + Inibidor de algas |

Alta adesão | Agente de acoplamento de éster de fosfato epóxi + silano |

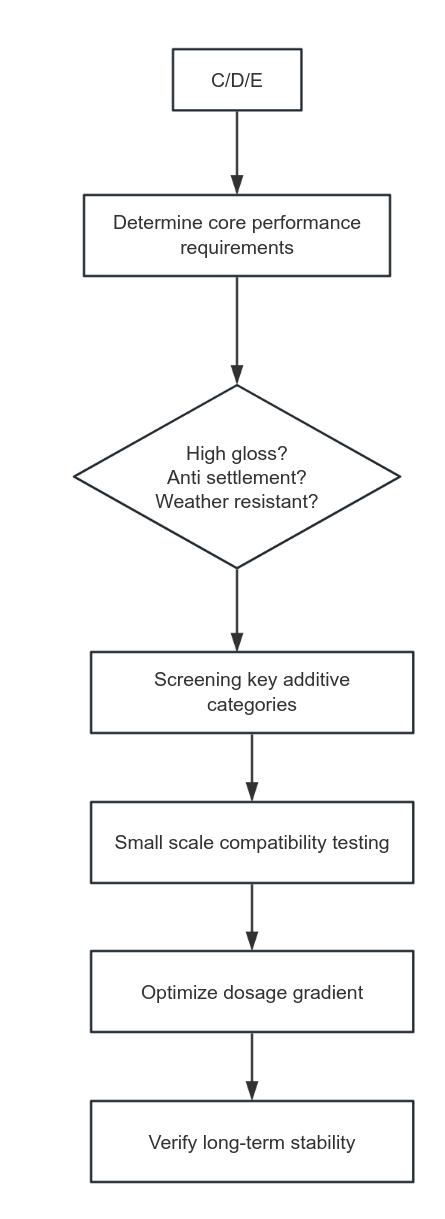

4.Verifique a estabilidade a longo prazo

Realize testes de envelhecimento acelerado (como armazenamento a 40 graus por 30 dias) para observar se:

l Assentamento (ajuste o agente anti-sedimentação)

l Alteração de viscosidade (ajuste do espessador)

l Desempenho antiespumante diminuído (hidrólise de antiespumantes)

5. Problemas e soluções comuns

Análise de Possibilidades | Ideias de Soluções | |

Encolhimento do filme de revestimento | Agentes niveladores ou antiespumantes incompatíveis | Substituir por aditivos compatíveis |

Sedimentação de pigmentos | Agente dispersante/anti-sedimentação insuficiente | Adicionar agente anti-sedimentação |

Baixo desempenho de nivelamento | Seleção inadequada de agente de nivelamento | Mudança para agente nivelador de silício orgânico |

Muita espuma | Agentes umectantes têm fortes propriedades espumantes | Ajuste o antiespumante |

Má adesão | Molhamento Insuficiente do Substrato | Adicionar agente de adesão |

6.Ideias gerais de seleção

O material determina o desempenho, e a seleção criteriosa de aditivos pode melhorar significativamente os defeitos de aplicação dos revestimentos. Recomenda-se otimizar a fórmula por meio de experimentos em pequena escala e atentar para o efeito sinérgico entre os aditivos. Somente com a aplicação correta é possível obter o máximo aproveitamento dos mesmos.

Grupo de Tecnologia Industrial AAB da China oferece um portfólio abrangente de aditivos e polímeros, bem como um atendimento personalizado e detalhado ao cliente para atender às necessidades específicas. Nossos principais produtos aditivos funcionais incluem: agentes umectantes e dispersantes, antiespumantes e liberadores de ar, agentes umectantes e niveladores, agentes de aderência e acoplamento, aditivos de cera, aditivos reológicos, agentes de cura HAA de alto desempenho, agentes de cura TIGC, resinas GMA, agentes de fosqueamento, agentes de nivelamento funcionais, agentes de textura, aditivos de carga, dispersantes, agentes de nivelamento e agentes de cura epóxi, dispersantes de pigmentos, modificadores de fluxo e umectantes, agentes antiamarelamento, aditivos de adesão, etc. Nossos produtos aditivos Kabasph® são amplamente utilizados em revestimentos automotivos, tintas de repintura, revestimentos marítimos, revestimentos anticorrosivos, revestimentos de madeira, tintas, tintas epóxi para pisos, revestimentos em pó, esmaltes em gel UV, têxteis, borracha, revestimentos arquitetônicos, fabricação de papel, etc. Plásticos, produtos para a pele, cosméticos, etc.

Se precisar de suporte técnico ou amostras grátis, sinta-se à vontade para entrar em contato conosco:

Tel.: +86 13951823978 (WhatsApp, Telegram)

E-mail: info@aabindustrygroup.com

Hi! Click one of our members below to chat on